vickers hardness test force|vickers hardness test calculator : import When doing the hardness tests, the minimum distance between indentations and the distance from the indentation to the edge of the specimen must be taken into account to avoid interaction between the work-hardened regions and effects of the edge. These minimum distances are different for ISO 6507-1 and ASTM E384 standards. Vickers values are generally independent of the test force: they will come out the same for 500 . WEBGiuliana Mafra Feet Pics. See more photos: Giuliana Mafra Bikini. When it comes to embracing one's individuality, Giuliana Mafra shines from head to toe - quite literally. .

{plog:ftitle_list}

WEBPrimeira vez da princesa sereia Shirahoshi com Luffy. Os piratas mais queridos da turma de Luffy em One Piece hentai pornô, com muito sexo neste anime, Nami transando com Luffy, Hancock trepando e muito mais.

The recommended Vickers hardness range can be found in the standard and standard ASTM E384. Depending on the test force and specimen material used, the Vickers hardness value lies between 1 and 3,000 HV.The recommended hardness ranges for Vickers tests, which depend on the .When doing the hardness tests, the minimum distance between indentations and the distance from the indentation to the edge of the specimen must be taken into account to avoid interaction between the work-hardened regions and effects of the edge. These minimum distances are different for ISO 6507-1 and ASTM E384 standards. Vickers values are generally independent of the test force: they will come out the same for 500 .

The recommended hardness ranges for Vickers tests, which depend on the applied test load and the type of specimen material, are specified in the ASTM E92 standard. These hardness .

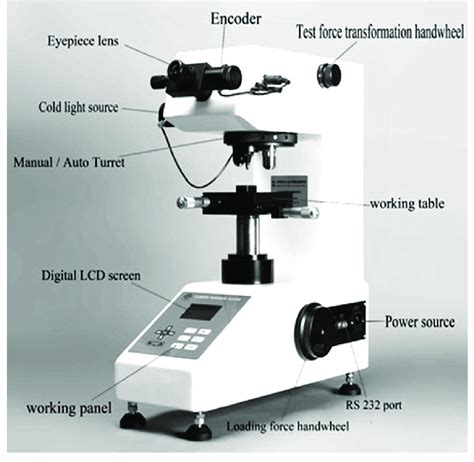

vickers hardness testing machine diagram

The Vickers Hardness number (HV) is the ratio of the load applied to the surface area of the indention. This is done with the following calculator and formula. HV = P / ( 0.5393 d 2 ) or. HV = 0.1891 F / d 2. Where: P = Force (kg) d = Area of .The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of which .Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three . The significant differences between the two tests are the geometries of the respective indenters, the method of calculation of the hardness numbers, and that Vickers .

The Vickers procedure can be used to test the hardness of metals and other equally hard materials. However, it was primarily designed to focus on softer materials like plastic specifically on their ability to resist deformation .Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three hardness testing load ranges: in the micro, low .This document specifies the Vickers hardness test method for the three different ranges of test force for metallic materials, including hard metals and other cemented carbides (see Table 1), .

A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds use in other materials like ceramics & some polymers, this test is widely employed in the metallurgical area.Hardness tests measure the resistance of a material against plastic deformation.To perform these tests (be it Brinell, Rockwell, or Vickers), an indenter is pressed on the surface of the specimen with a specific force F F F . For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the .

The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The geometrical shape of the indentation is always similar, while the load can be varied. The hardness testing load is the load (“force”) that is applied to the indenter when pressing into the material being tested. . Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding .

3.4 Vickers hardness test—an indentation hardness test using calibrated machines to force a square-based pyramidal diamond indenter having specified face angles, under a prede-termined force, into the surface of the material under test and to measure the diagonals of the resulting impression after removal of the force. 3.4.1 Vickers hardness .Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three hardness testing load ranges: in the micro, low-load and conventional (macro) hardness range.Vickers Hardness Testing Formulas, Calculator and Review . The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) or Diamond Pyramid Hardness ( DPH ). The hardness number can be converted into units of pascals , but .

E74 Practice of Calibration of Force-Measuring Instruments 3.1.5 Vickers hardness test, n—an indentation test in which for Verifying the Force Indication of Testing Machines a Vickers square-based pyramidal diamond indenter having E140 Hardness Conversion Tables for Metals Relationship specified face angles is forced under specified .The Vickers hardness test can be a micro indentation test and also for the macro hardness test. It is mainly divided into two steps. The test force (load) F is applied on the specified square base pyramid shaped diamond indenter for the specific time when it collides with the testing sample object in the direction normal to the test surface.

This part of ISO 6507 specifies the Vickers hardness test method, for the three different ranges of test force for metallic materials (see Table 1). Table 1 — Ranges of test force Ranges of test force, F N Hardness symbol Designation F W 49,03 W HV 5 Vickers hardness test 1,961 u F Low-force Vickers hardness test < 49,03 HV 0,2 to < HV 5numbers shall be followed by the symbol HV for Vickers hardness, or HK for Knoop hardness, and be supplemented by a value representing the test force in kgf. Examples: 450 HV 10 = Vickers hardness number of 450 obtained with a test force of 10 kgf, 700 HV 0.1 = Vickers hardness number of 700 obtained with a test force of 100 gf (0.1 kgf), 500

700 HV 10 / 20 ⇒ Hardness value as per Vickers . 700 HV 10 / 20 ⇒ Abbreviation for Vickers hardness . 700 HV 10 / 20 ⇒ Test force specification: Test force [N] = 9.807 * test force specification . 700 HV 10 / 20 ⇒ Application time of the test force (omitted if it is between 1-15 s)

Devised in the 1920s by engineers at Vickers, Ltd., in the United Kingdom, the diamond pyramid hardness test, as it also became known, Vickers hardness, a measure of the hardness of a material, calculated from the size of an impression produced under load by a pyramid-shaped diamond indenter. . (measured in kilograms-force) and D 2 the area .The two measurements are converted into a Vickers hardness (H V) value using the following equation: H V = 0.1891 * {F[N] / d1[mm] * d2[mm]} Sample Preparation. For a high-accuracy measurement, the test should be performed . EN ISO 6507-1 specifies he following are the three ranges of test force and their corresponding Vickers hardness test designations: F ≥ 49.03 N - Designation: HV 5 - Standard Vickers hardness test method for testing metals and materials with a medium to high hardness range. 1.961 ≤ F < 49.03 N - Designation: HV 0.2 to

1.1 Vickers Hardness. The Vickers test employs a square-based pyramid with an angle of 136° between opposing faces. . Vickers hardness is defined as the ratio of the force F acting on the diamond indenter (regular four-sided pyramid shape) and the surface A of the indentation .The Vickers hardness should be reported like 800 HV/10, which means a Vickers hardness of 800, was obtained using a 10 kgf force. Several different loading settings give practically identical hardness numbers on uniform material, which is much better than the arbitrary changing of scale with the other hardness testing methods.The Vickers hardness testing method is a static type, which follows the ISO 6507, ASTM E92, and ASTM E384 standards. This Vickers method has a test load ranging from 1 gf as per the ISO standards and from 1 gf up to 120 kgf according to the ASTM standards respectively.

vickers hardness test procedure pdf

The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384).Vickers Hardness Testing Knoop Hardness Testing Case Depth Hardness Testing . This distance is converted to a hardness number. The preliminary test force is removed and the indenter is removed from the test specimen. Preliminary test loads (preloads) range from 3 kgf (used in the “Superficial” Rockwell scale) to 10 kgf (used in the .The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. . Factors for the Selection of the Correct Test Force and Test Method.Vickers hardness (HV) according to ASTM E92 is calculated by the ratio of the applied test force F (expressed in Newtons, N) to the area of the permanent indentation on the test material. The average of the lengths of the two diagonals d1 and d2 (measured in millimeters) is used to determine the area of this pyramid-shaped indentation.

The Basics of Vickers Hardness Testing. Vickers Hardness Testing is based on a straightforward principle: the depth or size of an indentation left by an indenter in a material is directly proportional to the material's hardness. The Vickers test employs a pyramid-shaped diamond indenter with a square base angle of 136 degrees.Vickers hardness testing of small areas. A u: t o m a t i c e d i m e n s i o n s i b y A V P A K . hardness, you can set a test force that satisfies the JIS conditions. Used for selecting a conversion scale, entering a setting for Pass/Fail determination, and specifying external output.

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .

standarized test becoming harder statistics

vickers hardness test procedure

Descubra como o Gmail mantém a sua conta e os seus emai.

vickers hardness test force|vickers hardness test calculator